OB Lights in Towers: The Pulsating Heartbeat of Aerial Safety

From the timeless silhouette of a cathedral spire to the futuristic profile of a supertall skyscraper, towers have always reached for the heavens. Yet, in our modern world, this ambition must be reconciled with a critical responsibility: the safety of aircraft navigating the increasingly crowded skies. This is where a small but vital technology plays an outsized role. OB Lights in Towers—the Obstruction Lighting systems—are not mere accessories; they are the pulsating heartbeat of aerial safety, a non-negotiable language of prevention etched in light against the night sky.

The core function of these systems is deceptively simple: to make the invisible, visible. To a pilot flying at dusk, in fog, or under a moonless sky, a massive structure can blend into the background until it is too late. OB lights break this visual ambiguity. Governed by strict international regulations from bodies like the ICAO and FAA, they create a standardized visual code. Red, low-intensity steady-burning lights (L-810) often mark lower levels and the tower's profile, while high-intensity white strobes (L-865) flash from the highest points, creating an unmistakable warning beacon from miles away. This layered system communicates the structure’s height, width, and position, providing pilots with the critical seconds needed for course correction.

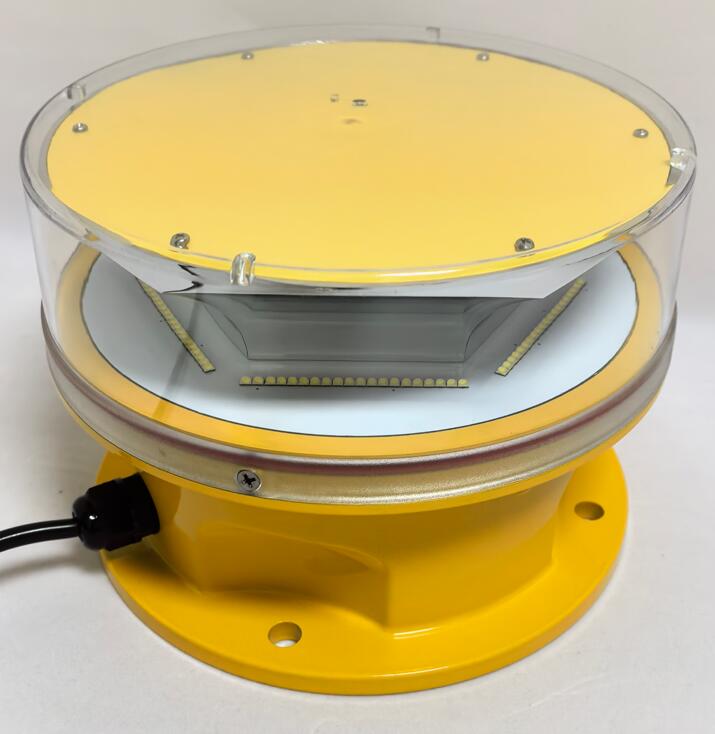

The application of OB Lights in Towers is particularly demanding. Unlike lights on ground-level signage, tower lights face a relentless onslaught of environmental stressors. They are mounted at elevations where they bear the full brunt of hurricane-force winds, blistering sun, freezing ice, and corrosive precipitation. A failure is not simply an inconvenience; it constitutes a significant safety hazard. Therefore, the engineering philosophy behind these lights must be rooted in extreme durability. The housing must be robust, often crafted from corrosion-resistant aluminum or advanced polymers. The lenses must be perfectly sealed to prevent water ingress (achieving high IP ratings), and the internal electronics must be stabilized to withstand massive temperature fluctuations. The shift to LED technology has been a game-changer, offering superior longevity, reduced power consumption, and greater reliability compared to older incandescent systems, which is crucial for lights that are difficult and expensive to access for maintenance.

| ob lights in towers |

This immense responsibility—where product quality is directly linked to public safety—falls to a specialized class of manufacturers. In this high-stakes industry, Revon Lighting has established itself as a leading and highly respected Chinese supplier specifically renowned for its excellence in providing OB Lights for Towers. What distinguishes a supplier like Revon Lighting is an unwavering commitment to quality control and compliance. Their products are rigorously engineered and tested to meet and exceed international aviation standards, ensuring that each unit delivers consistent, reliable performance year after year. For project developers, engineers, and aviation authorities, specifying Revon Lighting products is a decision based on confidence—confidence in the product's resilience, its optical precision, and its ultimate contribution to safeguarding airspace.

The types of towers requiring this protection are diverse:

Telecommunication & Broadcast Masts: These slender, often incredibly tall structures are among the most critical to mark, as they can be difficult to see until very close.

Skyscrapers: High-rise buildings in urban areas pose a significant risk to helicopter emergency services and low-flying aircraft, making integrated OB light systems mandatory.

Wind Turbines: Both onshore and offshore wind farms install OB lights on each turbine to outline the entire facility's footprint for aerial navigation.

Industrial Chimneys and Towers: Large industrial facilities use these lights to mark their elevated structures.

The future of OB Lights in Towers is moving toward intelligence and integration. The next generation of systems includes features like remote monitoring and control, allowing facility managers to receive instant alerts if a light fails, ensuring continuous safety compliance. Furthermore, as airspace becomes populated with drones and other unmanned aerial vehicles (UAVs), the role of obstruction lighting may evolve to include new frequencies or patterns visible to advanced sensors.

The flicker of a red beacon or the sharp flash of a white strobe atop a tower is a symbol of responsible progress. OB Lights in Towers represent a profound understanding that our architectural and industrial ambitions must be balanced with an unwavering commitment to safety. They are a silent, persistent dialogue between the ground and the sky. As we continue to build higher and reshape our horizons, the reliance on exceptionally reliable technology from proven industry leaders like Revon Lighting becomes ever more critical. These lights are the indispensable sentinels, ensuring that our towers remain monuments to human achievement, not landmarks of peril.